APPLICATION

The evaporative condenser is one of the most important parts of the whole refrigeration system. The condenser condenses the refrigerant gas inside the coil and complete a heat exchange circle. The evaporative condenser is widely applied to cold storage, ice-store, chemical industry, supermarket and etc.

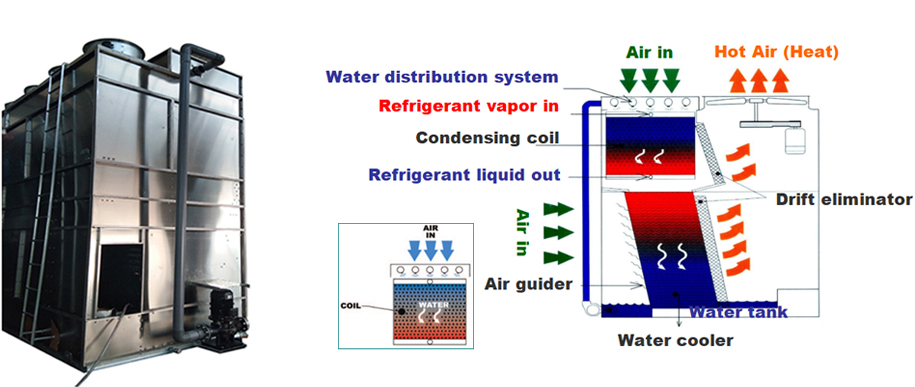

WORKING PRINCIPLE

During operation, the cooling water is pumped up to the top nozzle and evenly sprayed onto the outer surface of condensing coil and form a water layer.

The high temperature refrigerant gas come out from compressor and get into the condensing coils. Under a high speed wind bring by the fans on the top, the water layer on the outer surface of condensing coil evaporates and takes away the heat of the refrigerant. The refrigerant condenses into liquid and flow back to the compressor. Some water absorb heat and become steam, the rest water drop into the water tank for re-circulation. The hot steam is blown out from top and rest vapour remain on the top water stopper. The floating valve in the tank control water supplement into the tank automatically.

FEATURES

- Power-saving; Water-saving; Space-saving

- High Heat Exchange Ability

- Easy to install

- Low maintenance cost

- Long lifetime

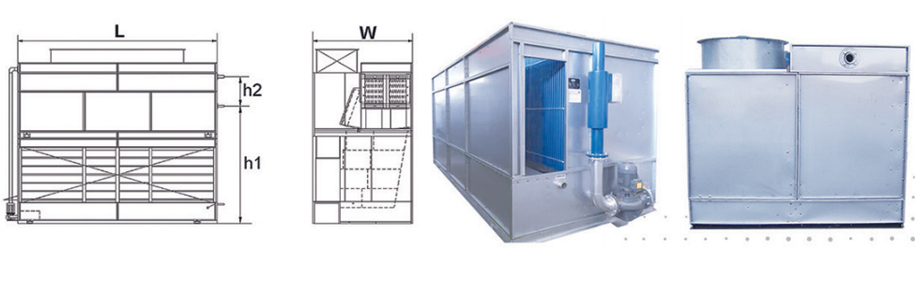

PARALLEL FLOW ECB SERIES

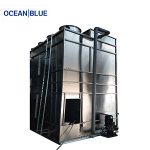

PRODUCT DISPLAY

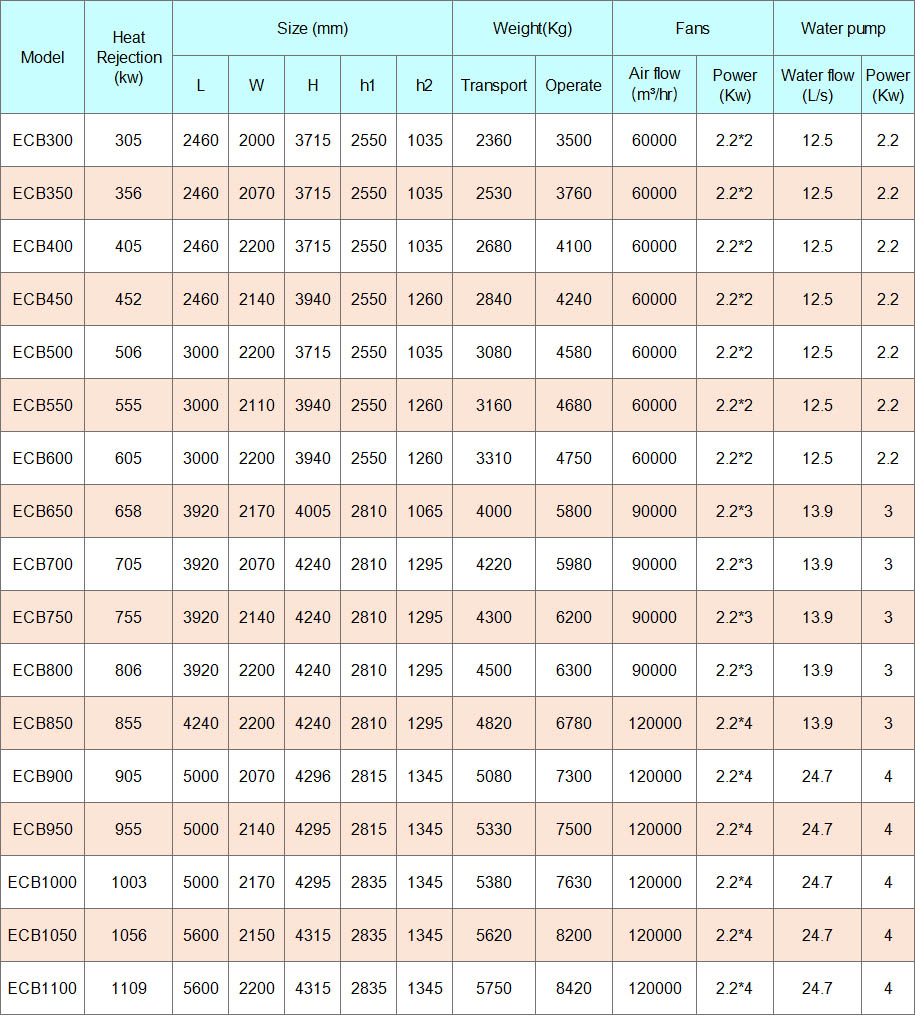

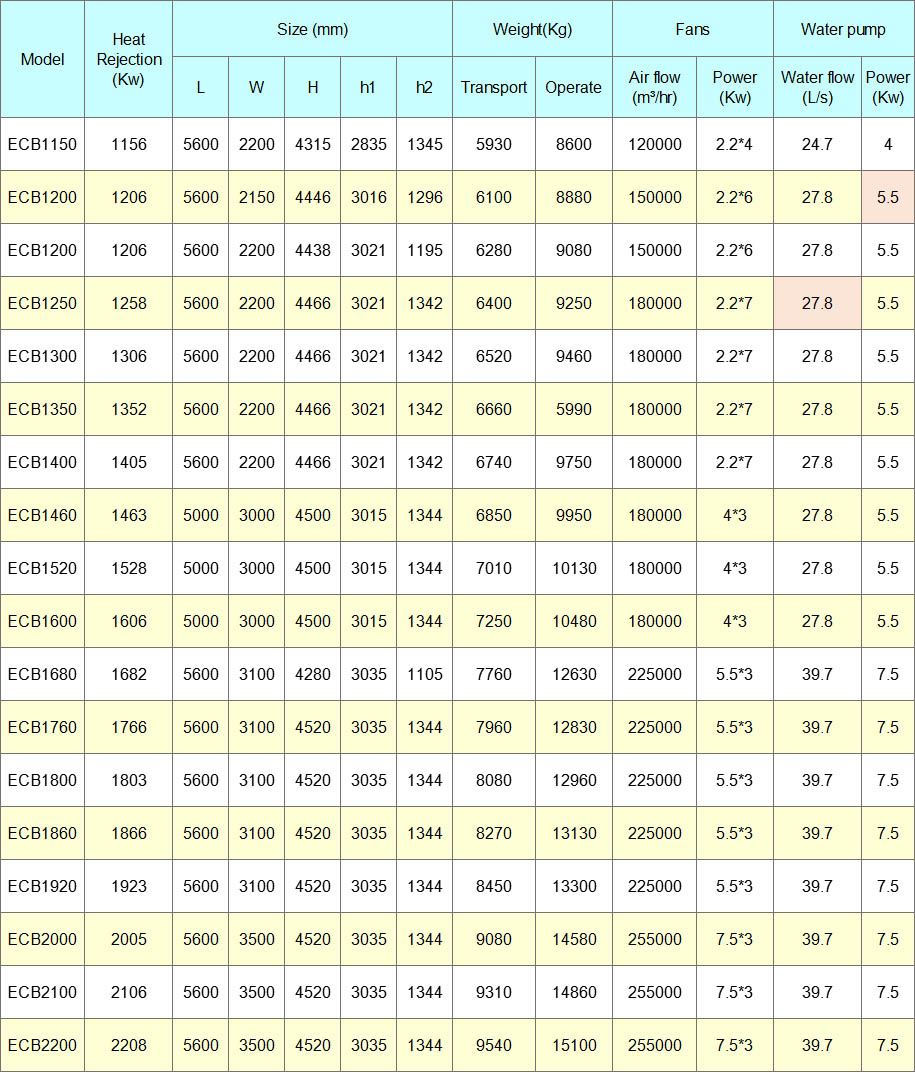

MODEL & SPECS ECB SERIES

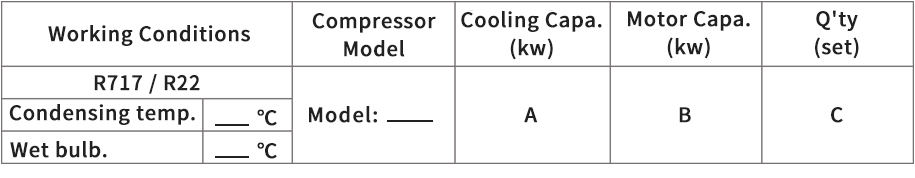

HOW TO CHOOSE A RIGHT MODEL

Compressor conditions

Condensing capacity calculating

Total cooling capa. and motor capa. of the compressors: (A + B) × C

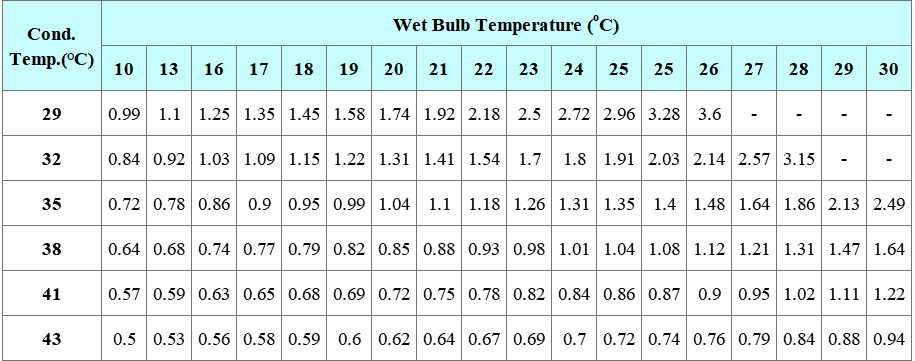

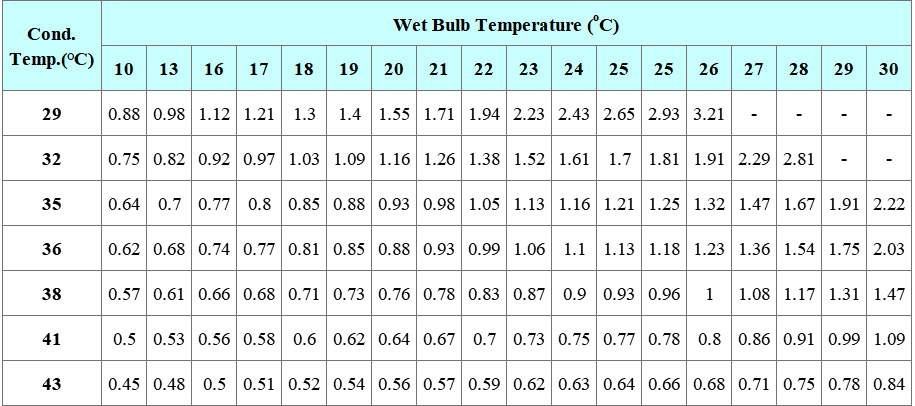

Obtain a factor from Table 1/2 according to condensing temp. and wet bulb: t

Total condensing capacity of of the evaporative condenser: (A + B)×C×t

For example:

Given:

Compressor: R717; cooling capa. 335Kw; motor power 90Kw; 2 sets

Working conditions: Condensing temp. 35oC and wet bulb temp. 28oC)

Selection:

(335+90)×2×1.67=1419.5Kw

Therefore, select an OceanBlue model ECB1460 with condensing capacity of 1466Kw.

Table 1 – R22 and R134a Heat Rejection Factors

Table 2 – Ammonia (R-717) Heat Rejection Factors

PACKAGING

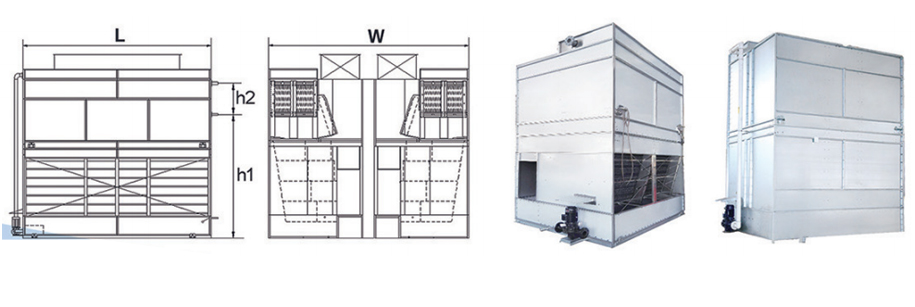

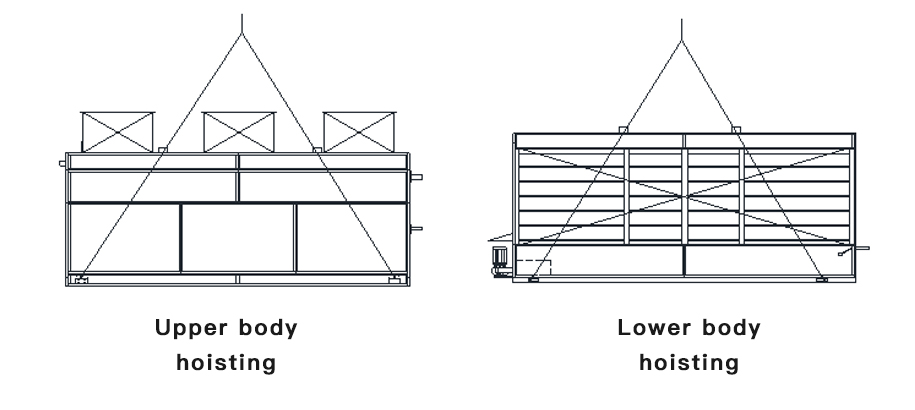

TRANSPORT & INSTALLATION

The Evaporation condensers are designed with two or four module parts, all the condensers are transported separately assembled at site, easy to install and save time and labor cost.

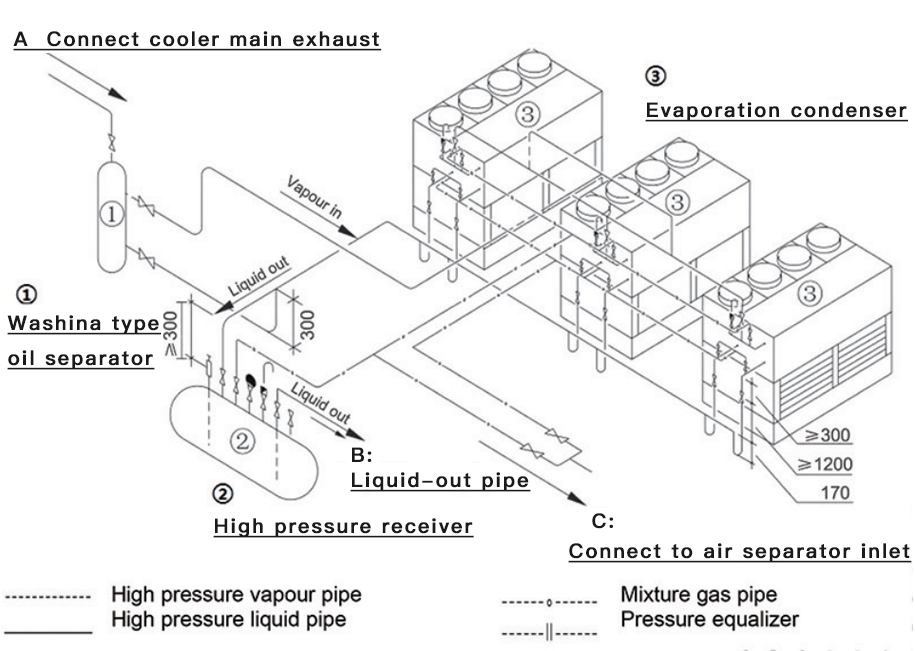

PARALLEL FLOW SYSTEM COUNSTRUCTION